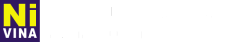

Rockwell hardness testing machine HR-430MR

Rockwell hardness testing machine HR-430MR

Model: 810-193-21

Brand: mitutoyo

Origin: Japan

概要

The HR-430MR is an economical Rockwell hardness testing machine to suit practically every application you need. The MR indicates the Rockwell testforce range.

It offers you the following benefits:

- The frame was designed with great care to provide maximum clearance for positioning the work piece. All you need is a flat table for mounting these testing machines.

- Its outstanding robustness makes it perfect for even the roughest environments.

- The HR-430MR is very simple to operate. It uses automatic steering wheel braking and load sequencing for easy handling.

- You can attach the clamping device K543817 to for safe operation with hard to handle workpieces.

- This digital model can use our Digimatic Mini-processor (DP-1VR) for printing results, and you can use an input tool (USB-ITN-E) to connect to a PC for data transfer, analysis and storage.

- You can perform Brinell hardness tests, as indicated, by using the following optional accessories:

a Brinell indenter and a measurement microscope.

- Standard: JIS B 7726; ISO6508-2; ASTM E18

- Preliminary test force (N): 98,07

- Test force Superficial (N): -

- Test force Rockwell (N): 588,4; 980,7; 1471

- Model: HR-430MR

- Rockwell Scale Diamond: HRA; HRD; HRC

- Rockwell Scale Ball 1,5875 mm: HRFW; HRBW; HRGW

- Rockwell Scale Ball 3,175 mm: HRHW; HREW; HRKW

- Rockwell Scale Ball 6,35 mm: HRLW; HRMW; HRPW

- Rockwell Scale Ball 12,7 mm: HRRW; HRSW; HRVW

- Description:

The HR-430MR is an economical Rockwell hardness testing machine to suit practically every application you need. The MR indicates the Rockwell testforce range.

It offers you the following benefits:

- The frame was designed with great care to provide maximum clearance for positioning the work piece. All you need is a flat table for mounting these testing machines.

- Its outstanding robustness makes it perfect for even the roughest environments.

- The HR-430MR is very simple to operate. It uses automatic steering wheel braking and load sequencing for easy handling.

- You can attach the clamping device K543817 to for safe operation with hard to handle workpieces.

- This digital model can use our Digimatic Mini-processor (DP-1VR) for printing results, and you can use an input tool (USB-ITN-E) to connect to a PC for data transfer, analysis and storage.

- You can perform Brinell hardness tests, as indicated, by using the following optional accessories:

a Brinell indenter and a measurement microscope.

- Resolution: 0,1 HR indication

- Test force selection: Dial switching

- Test force application: Automatic

- Test force duration: Settable 1-99s.

- Data output: Digimatic (SPC), RS-232C

- Height: Max. 180 mm (100 if cover is attached) mm

- Measuring depth: Max. 165 mm (from the center of the endenter axis)

- Functions: GO/NG, Hardness value offset, Hardness conversion, Data output, Calibration mode

- Display Unit: Matrix backlight LCD

- Main unit dimensions: 214x512x780mm

- Brinell Scales indentation only Ball 1,0 mm: HBW 1/10; HBW 1/30 - nur Eindruck (nicht normgerecht durch Anwendung der Prüfvorkraft)

- Brinell Scales indentation only Ball 10,0 mm: HBW 10/100 - nur Eindruck (nicht normgerecht durch Anwendung der Prüfvorkraft)

- HR unit resolution: 0,1 HR

- Jominy-test capability: Additional accessories required

- Workpiece clamping device K543817 capability: Serial

- Anvil adaption: Ø 19mm

- Max. specimen height: 180 mm

- Throat depth: 165 mm

- Max. specimen weight: 20 kg

- Approx. mass main unit: 49,3 kg

- Gross Weight: 70,000 [gram]

- Standard accessories:

810-39 Flat anvil Ø64mm

810-40 V-anvil outside diameter Ø40mm groove width 30mm

11AAB941 Water level

383876 Vinyl cover

357651 AC adaptor

Indenters, reference materials and power cord not included

- Net weight: 49,300 [gram]

応用

- Standard: JIS B 7726; ISO6508-2; ASTM E18

- Preliminary test force (N): 98,07

- Test force Superficial (N): -

- Test force Rockwell (N): 588,4; 980,7; 1471

- Model: HR-430MR

- Rockwell Scale Diamond: HRA; HRD; HRC

- Rockwell Scale Ball 1,5875 mm: HRFW; HRBW; HRGW

- Rockwell Scale Ball 3,175 mm: HRHW; HREW; HRKW

- Rockwell Scale Ball 6,35 mm: HRLW; HRMW; HRPW

- Rockwell Scale Ball 12,7 mm: HRRW; HRSW; HRVW

- Description:

The HR-430MR is an economical Rockwell hardness testing machine to suit practically every application you need. The MR indicates the Rockwell testforce range.

It offers you the following benefits:

- The frame was designed with great care to provide maximum clearance for positioning the work piece. All you need is a flat table for mounting these testing machines.

- Its outstanding robustness makes it perfect for even the roughest environments.

- The HR-430MR is very simple to operate. It uses automatic steering wheel braking and load sequencing for easy handling.

- You can attach the clamping device K543817 to for safe operation with hard to handle workpieces.

- This digital model can use our Digimatic Mini-processor (DP-1VR) for printing results, and you can use an input tool (USB-ITN-E) to connect to a PC for data transfer, analysis and storage.

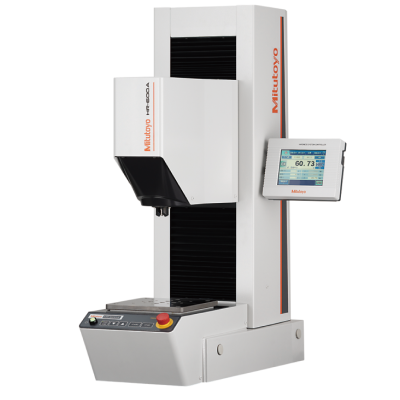

- You can perform Brinell hardness tests, as indicated, by using the following optional accessories:

a Brinell indenter and a measurement microscope.

- Resolution: 0,1 HR indication

- Test force selection: Dial switching

- Test force application: Automatic

- Test force duration: Settable 1-99s.

- Data output: Digimatic (SPC), RS-232C

- Height: Max. 180 mm (100 if cover is attached) mm

- Measuring depth: Max. 165 mm (from the center of the endenter axis)

- Functions: GO/NG, Hardness value offset, Hardness conversion, Data output, Calibration mode

- Display Unit: Matrix backlight LCD

- Main unit dimensions: 214x512x780mm

- Brinell Scales indentation only Ball 1,0 mm: HBW 1/10; HBW 1/30 - nur Eindruck (nicht normgerecht durch Anwendung der Prüfvorkraft)

- Brinell Scales indentation only Ball 10,0 mm: HBW 10/100 - nur Eindruck (nicht normgerecht durch Anwendung der Prüfvorkraft)

- HR unit resolution: 0,1 HR

- Jominy-test capability: Additional accessories required

- Workpiece clamping device K543817 capability: Serial

- Anvil adaption: Ø 19mm

- Max. specimen height: 180 mm

- Throat depth: 165 mm

- Max. specimen weight: 20 kg

- Approx. mass main unit: 49,3 kg

- Gross Weight: 70,000 [gram]

- Standard accessories:

810-39 Flat anvil Ø64mm

810-40 V-anvil outside diameter Ø40mm groove width 30mm

11AAB941 Water level

383876 Vinyl cover

357651 AC adaptor

Indenters, reference materials and power cord not included

- Net weight: 49,300 [gram]