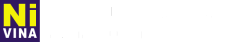

Vickers hardness testing machine HV-120 System main unit A-type

Vickers hardness testing machine HV-120 System main unit A-type

Model: 810-445D

Brand: mitutoyo

Origin: Japan

概要

The manual line up of the HV-100 Series has the following benefits:

- 144 mm (5.7 inch) colored touchsreen display (Type A) with higher visibility, easy to operate user interface

- Digimatic output for report creation.

- USB stick data export

- Electronic test force change.

- Max. specimen height up to 210mm

- LED illumination for best image.

- High number of accessories

- Vickers, Knoop, Brinell and KC fracture toughness measurement.

- Supports Brinelltest up to 62,5KG with an optional test force weight.

- External dimensions [mm]: System A: 307(W)×696(D)×786(H)mm System B/C/D: 307(W)×627(D)×875(H)mm

- Objective lens: Up to 3 pcs. mountable (one standard lens 10X mounted as standard)

- Force dwell time: 5-999 sec (selectable)

- Optical system: Infinity corrected optical system

- Illumination unit: LED light

- Test force:

N: 2,942; 4,903; 9,807; 24,51; 49,03; 98,07; 196,1; 294,2

(kgf): 0,3; 0,5; 1; 2,5; 5; 10; 20; 30

- Power supply report: UN 38.3 Test Summary Report

- Standard: JIS B 7725, ISO 6507-2

- Data output: RS-232C, Digimatic, USB 2. 0 interface

- Indenter approach speed: 60 µm/s, 150 µm/s selectable

- Control panel: Built-in touch panel, 5.7" Color LCD (HM-110A/120A for System A), Control software (PC for System B/C/D)

- Functions: Calculation of Vickers / Knoop*2 / Brinell*3 hardness, and ceramic fracture toughness based on IF method (JIS R1697), 3 display format (standard, list, simple), GO/NG judgment, test condition guide, curve and user correction, hardness corresponding value, statistics calculation

- Main unit mass: HV-110: Approx. 60kg, HV-120: Approx. 58kg

- Output: Digimatic, serial, USB2.0 series A (for memory)*1, USB2.0 B Type (for system communication)

- Resolution of diagonal length of an indentation: Objective lens less than 50X: 0.1μm (Objective lens more than 50X: 0.01μm)

- Specimen dimensions:

System A: height 210mm, depth 170mm (when using flat anvil)

System B: height 181mm, depth 170mm (when using manual XY stage 50X50mm)

System C: height 172mm, depth 170mm, System D: height 132mm, depth 170mm

- Test force control: Lever method and automatic control (load, duration, unload)

- Turret drive: Motor driven and manual operation

応用

仕様

- External dimensions [mm]: System A: 307(W)×696(D)×786(H)mm System B/C/D: 307(W)×627(D)×875(H)mm

- Objective lens: Up to 3 pcs. mountable (one standard lens 10X mounted as standard)

- Force dwell time: 5-999 sec (selectable)

- Optical system: Infinity corrected optical system

- Illumination unit: LED light

- Test force:

N: 2,942; 4,903; 9,807; 24,51; 49,03; 98,07; 196,1; 294,2

(kgf): 0,3; 0,5; 1; 2,5; 5; 10; 20; 30

- Power supply report: UN 38.3 Test Summary Report

- Standard: JIS B 7725, ISO 6507-2

- Data output: RS-232C, Digimatic, USB 2. 0 interface

- Indenter approach speed: 60 µm/s, 150 µm/s selectable

- Control panel: Built-in touch panel, 5.7" Color LCD (HM-110A/120A for System A), Control software (PC for System B/C/D)

- Functions: Calculation of Vickers / Knoop*2 / Brinell*3 hardness, and ceramic fracture toughness based on IF method (JIS R1697), 3 display format (standard, list, simple), GO/NG judgment, test condition guide, curve and user correction, hardness corresponding value, statistics calculation

- Main unit mass: HV-110: Approx. 60kg, HV-120: Approx. 58kg

- Output: Digimatic, serial, USB2.0 series A (for memory)*1, USB2.0 B Type (for system communication)

- Resolution of diagonal length of an indentation: Objective lens less than 50X: 0.1μm (Objective lens more than 50X: 0.01μm)

- Specimen dimensions:

System A: height 210mm, depth 170mm (when using flat anvil)

System B: height 181mm, depth 170mm (when using manual XY stage 50X50mm)

System C: height 172mm, depth 170mm, System D: height 132mm, depth 170mm

- Test force control: Lever method and automatic control (load, duration, unload)

- Turret drive: Motor driven and manual operation