- Ứng dụng

- SẢN PHẨM

- Kính hiển vi công nghiệp

- Camera & Phần mềm đo lường

- Thiết bị đo lường NIKON

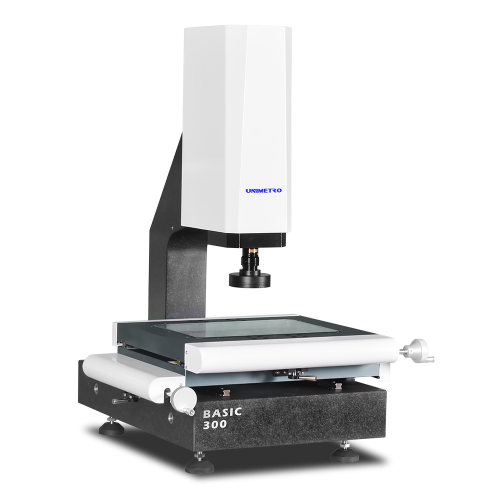

- Máy đo quang học (2D/3D) Trung Quốc

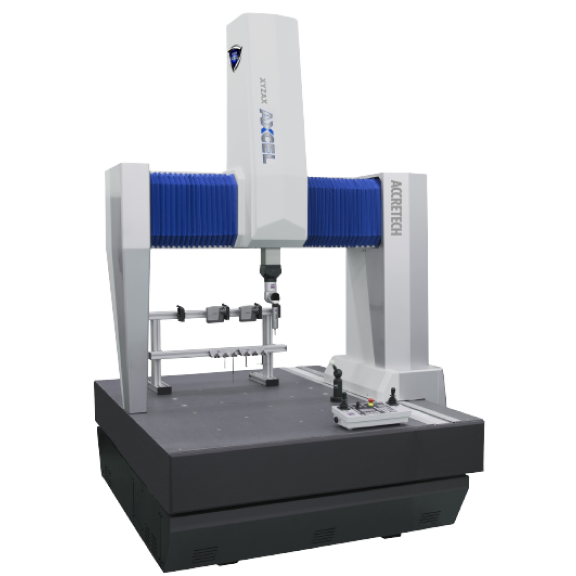

- Máy đo chạm 3D

- Máy Đo bề mặt và biên dạng

- Thiết bị đo công nghiệp

- Thiết bị đo hiện trường

- Thiết bị đo kiểm điện áp, cường độ, công suất

- THIẾT BỊ GHI DỮ LIỆU ĐA KÊNH

- THIẾT BỊ ĐO LCR, THIẾT BỊ PHÂN TÍCH TRỞ KHÁNG, ĐO ĐIỆN DUNG

- THIẾT BỊ GHI DỮ LIỆU NHỎ GỌN, THIẾT BỊ GHI DỮ LIỆU NHIỆT ĐỘ

- THIẾT BỊ ĐO ĐIỆN TRỞ, THIẾT BỊ KIỂM TRA PIN

- THIẾT BỊ ĐO SIÊU ĐIỆN TRỞ

- THIẾT BỊ KIỂM TRA AN TOÀN ĐIỆN, THIẾT BỊ ĐO ĐIỆN TRỞ CÁCH ĐIỆN/DÒNG RÒ/HIPOT

- THIẾT BỊ PHÂN TÍCH CHẤT LƯỢNG ĐIỆN, THIẾT BỊ GHI CÔNG SUẤT

- ĐẦU ĐO / CẢM BIẾN DÒNG ĐIỆN, ĐẦU ĐO ĐIỆN ÁP, CẢM BIẾN CAN

- TỪ TRƯỜNG, NHIỆT ĐỘ, MỨC ÂM THANH, LUX, XOAY

- Thiết bị đo áp suất và cảm biến áp suất

- Máy đo kiểm trong phòng thí nghiệm

- THƯƠNG HIỆU

- Về chúng tôi

- Tin tức