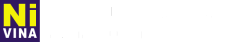

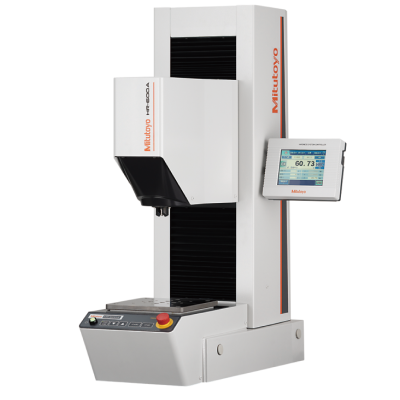

Rockwell Hardness Testing Machine HR-610A

Rockwell Hardness Testing Machine HR-610A

Model: 810-512-23

Brand: mitutoyo

Origin: Japan

Summary

With innovative design and functionality that enables a wide variety of measurements, the HR-600 Series delivers hardness testing that defies conventional thinking.

Go above and beyond

- High-End CNC Rockwell Hardness Testing Machine, providing a fully automatic Rockwell hardness test sequence.

- It is operated either with the provided display unit or by the use of AVPAK 3.1 hardness testing software (11AAE525-DEE AVPAK for HR-600A).

- When run with AVPAK 3.1, it can easily be integrated in an automation cell via the programmable Mitutoyo Form EIO automation interface.

The HR-600 Series combines the functionality of several test methods:

- Rockwell hardness testing

- Brinell hardness testing (indentation only)

- Brinell depth measurement hardness testing

- Vickers depth measurement hardness testing

- Hardness testing of plastic materials

Supporting all test methods in a single machine, this new series expands the range of available measurements.

With its high-resolution scale load cell developed uniquely by Mitutoyo that allows for high-precision test load feedback control and state-of-the-art design that delivers both aesthetics and usability on the ground, the new HR-600 Series enables hardness testing that defies conventional thinking.

New design with functional beauty.

With a table for mounting workpieces and head with vertical mobility, the HR-600 Series is built for operability and usability.

Its new design is highly focused on end-user usability, and the entire product structure has been inventively modified for functional beauty — a true embodiment of Mitutoyo’s pioneering spirit.

Indenters, hardness reference aterials and power cord are not included in the scope of delivery and must be ordered separately.

Attention:

* requires optional accessories

** more on request

*** can be enhanced with additional accesories

- Rockwell Scale Diamond: HRA; HRC, HRD

- Rockwell Scale Ball 1,5875 mm: HRFW; HRBW; HRGW

- Rockwell Scale Ball 3,175 mm: HRHW; HREW; HRKW

- Rockwell Scale Ball 6,35 mm: HRLW; HRMW; HRPW

- Rockwell Scale Ball 12,7 mm: HRRW; HRSW; HRVW

- Rockwell Superficial Scale Diamond: HR15N; HR30N; HR45N

- Rockwell Superficial Scale Ball 1,5875 mm: HR15TW, HR30TW; HR45TW

- Rockwell Superficial Scale Ball 3,175 mm: HR15WW, HR30WW; HR45WW

- Rockwell Superficial Scale Ball 6,35 mm: HR15XW, HR30XW; HR45XW

- Rockwell Superficial Scale Ball 12,7 mm: HR15YW, HR30YW; HR45YW

- Rockwell Plastic Test Scales Ball 3,175 mm: HRE; HRK

- Rockwell Plastic Test Scales Ball 6,35 mm: HRL; HRM

- Rockwell Plastic Test Scales Ball 12,7 mm: HRR

- Rockwell α Test Ball 12,7 mm: (HRR)

- Max. specimen weight X-axis: 50kg

- Basic test surface 200 x 200mm: Yes

- Applicable test methods and standards:

Rockwell, Rockwell Superficial (EN ISO 6508, ASTM E-18, JIS B7726)

Plastic test (EN ISO 2039-2, ASTM D785 A, JIS K7202-2)

Rockwell Alpha test (ASTM D785 B)

Brinell, Indentation only (EN ISO 6506, ASTM E-10, JIS B7724)

HBT (VDE/VDI 2616 - non standard)

HVT (VDE/VDI 2616 - non standard)

- Brinell: HBW 1/10; HBW 2.5/6.25; HBW 5/25; HBW 10/100; HBW 1/30; HBW 2.5/15.625; HBW 5/62.5; HBW 2.5/31.25; HBW 5/125; HBW 2.5/62.5; HBW 2.5/187.5

- Brinell Depth Measurement: HBD 2.5/62.5; HBD 2.5/187.5

- Rockwell Plastic test: HRE; HRL; HRR; HRK; HRM

- Rockwell α plastic test: (HRR)

- Functionality:

5,7" touch screen display

mm

HR unit resolution: 0,01

Test force range 3-187,5kg, 2,94-1839N

Test force switching by software

Real time test force control

Fully automatic test cycle

Motorized test force generation

Motorized Z-Axis

LED workroom illumination

RS-232C Digimatic, USB2.0 interface

USB stick data transfer

Jominy-test capability*

Footswitch connection for serial test

- Functional dimensions:

Contact unit contact area: ** 18x4mm

Minimum inside radius of workpiece: 25mm

Minimum inside Ø of workpiece: 400mm

Minimum outside radius of workpiece: 20mm

Basic test surface 200 x 200mm ***

Anvil adaption Ø 10mm / Ø 19mm (optional)

Max. specimen height (reduced by adding accessories and X-axis): 250mm

X-axis option: (optional)

Z-axis height (Max. specimen height: 250mm

Z-axis height with X-axis added (Max. specimen height): 165mm

Throat depth: 220mm

Max. specimen weight: 100kg

Max. specimen weight with X-axis mounted: 50kg

Max. speed Z: 10mm/sec

- Main unit dimensions:

External dimensions 350(W) × 681(D) × 935(H) mm

External dimensions display unit 191(W) × 71(D) × 147(H) mm

Mass main unit: 181kg

Power supply AC100V, 120V, 220V, 240V Auto-selection

Power cord not included

Operation temperature 5-40 °C

Humidity 55-65% (without dew condensation)

- Model: HR-610A

- Brinell Scales indentation only Ball 1,0 mm: HBW 1/5; 1/10; HBW 1/30

- Brinell Scales indentation only Ball 2,5 mm: HBW 2.5/6.25; HBW 2.5/15.625; HBW 2.5/31.25; HBW 2.5/62.5; HBW 2.5/187.5

- Brinell Scales indentation only Ball 5,0 mm: HBW 5/25; HBW 5/62.5; HBW 5/125

- Brinell Scales indentation only Ball 10,0 mm: HBW 10/100

- Brinell depth measurement Ball 2,5 mm: HBD 2.5/62.5; HBD 2.5/187.5

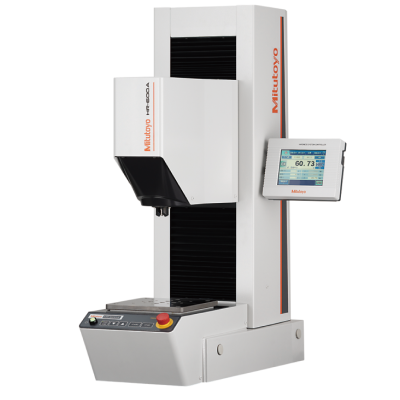

Application

With innovative design and functionality that enables a wide variety of measurements, the HR-600 Series delivers hardness testing that defies conventional thinking.

Go above and beyond

- High-End CNC Rockwell Hardness Testing Machine, providing a fully automatic Rockwell hardness test sequence.

- It is operated either with the provided display unit or by the use of AVPAK 3.1 hardness testing software (11AAE525-DEE AVPAK for HR-600A).

- When run with AVPAK 3.1, it can easily be integrated in an automation cell via the programmable Mitutoyo Form EIO automation interface.

The HR-600 Series combines the functionality of several test methods:

- Rockwell hardness testing

- Brinell hardness testing (indentation only)

- Brinell depth measurement hardness testing

- Vickers depth measurement hardness testing

- Hardness testing of plastic materials

Supporting all test methods in a single machine, this new series expands the range of available measurements.

With its high-resolution scale load cell developed uniquely by Mitutoyo that allows for high-precision test load feedback control and state-of-the-art design that delivers both aesthetics and usability on the ground, the new HR-600 Series enables hardness testing that defies conventional thinking.

New design with functional beauty.

With a table for mounting workpieces and head with vertical mobility, the HR-600 Series is built for operability and usability.

Its new design is highly focused on end-user usability, and the entire product structure has been inventively modified for functional beauty — a true embodiment of Mitutoyo’s pioneering spirit.

Indenters, hardness reference aterials and power cord are not included in the scope of delivery and must be ordered separately.

Attention:

* requires optional accessories

** more on request

*** can be enhanced with additional accesories

Specifications

- Rockwell Scale Diamond: HRA; HRC, HRD

- Rockwell Scale Ball 1,5875 mm: HRFW; HRBW; HRGW

- Rockwell Scale Ball 3,175 mm: HRHW; HREW; HRKW

- Rockwell Scale Ball 6,35 mm: HRLW; HRMW; HRPW

- Rockwell Scale Ball 12,7 mm: HRRW; HRSW; HRVW

- Rockwell Superficial Scale Diamond: HR15N; HR30N; HR45N

- Rockwell Superficial Scale Ball 1,5875 mm: HR15TW, HR30TW; HR45TW

- Rockwell Superficial Scale Ball 3,175 mm: HR15WW, HR30WW; HR45WW

- Rockwell Superficial Scale Ball 6,35 mm: HR15XW, HR30XW; HR45XW

- Rockwell Superficial Scale Ball 12,7 mm: HR15YW, HR30YW; HR45YW

- Rockwell Plastic Test Scales Ball 3,175 mm: HRE; HRK

- Rockwell Plastic Test Scales Ball 6,35 mm: HRL; HRM

- Rockwell Plastic Test Scales Ball 12,7 mm: HRR

- Rockwell α Test Ball 12,7 mm: (HRR)

- Max. specimen weight X-axis: 50kg

- Basic test surface 200 x 200mm: Yes

- Applicable test methods and standards:

Rockwell, Rockwell Superficial (EN ISO 6508, ASTM E-18, JIS B7726)

Plastic test (EN ISO 2039-2, ASTM D785 A, JIS K7202-2)

Rockwell Alpha test (ASTM D785 B)

Brinell, Indentation only (EN ISO 6506, ASTM E-10, JIS B7724)

HBT (VDE/VDI 2616 - non standard)

HVT (VDE/VDI 2616 - non standard)

- Brinell: HBW 1/10; HBW 2.5/6.25; HBW 5/25; HBW 10/100; HBW 1/30; HBW 2.5/15.625; HBW 5/62.5; HBW 2.5/31.25; HBW 5/125; HBW 2.5/62.5; HBW 2.5/187.5

- Brinell Depth Measurement: HBD 2.5/62.5; HBD 2.5/187.5

- Rockwell Plastic test: HRE; HRL; HRR; HRK; HRM

- Rockwell α plastic test: (HRR)

- Functionality:

5,7" touch screen display

mm

HR unit resolution: 0,01

Test force range 3-187,5kg, 2,94-1839N

Test force switching by software

Real time test force control

Fully automatic test cycle

Motorized test force generation

Motorized Z-Axis

LED workroom illumination

RS-232C Digimatic, USB2.0 interface

USB stick data transfer

Jominy-test capability*

Footswitch connection for serial test

- Functional dimensions:

Contact unit contact area: ** 18x4mm

Minimum inside radius of workpiece: 25mm

Minimum inside Ø of workpiece: 400mm

Minimum outside radius of workpiece: 20mm

Basic test surface 200 x 200mm ***

Anvil adaption Ø 10mm / Ø 19mm (optional)

Max. specimen height (reduced by adding accessories and X-axis): 250mm

X-axis option: (optional)

Z-axis height (Max. specimen height: 250mm

Z-axis height with X-axis added (Max. specimen height): 165mm

Throat depth: 220mm

Max. specimen weight: 100kg

Max. specimen weight with X-axis mounted: 50kg

Max. speed Z: 10mm/sec

- Main unit dimensions:

External dimensions 350(W) × 681(D) × 935(H) mm

External dimensions display unit 191(W) × 71(D) × 147(H) mm

Mass main unit: 181kg

Power supply AC100V, 120V, 220V, 240V Auto-selection

Power cord not included

Operation temperature 5-40 °C

Humidity 55-65% (without dew condensation)

- Model: HR-610A

- Brinell Scales indentation only Ball 1,0 mm: HBW 1/5; 1/10; HBW 1/30

- Brinell Scales indentation only Ball 2,5 mm: HBW 2.5/6.25; HBW 2.5/15.625; HBW 2.5/31.25; HBW 2.5/62.5; HBW 2.5/187.5

- Brinell Scales indentation only Ball 5,0 mm: HBW 5/25; HBW 5/62.5; HBW 5/125

- Brinell Scales indentation only Ball 10,0 mm: HBW 10/100

- Brinell depth measurement Ball 2,5 mm: HBD 2.5/62.5; HBD 2.5/187.5