X-RAY CT XT H 225

X-RAY CT XT H 225

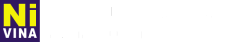

Model: XT H-225

Brand: Nikon

Origin:

Summary

X-ray Nikon XT H 225:

The X-ray Nikon XT H 225 is a cutting-edge X-ray imaging system designed to provide high-resolution and accurate inspection capabilities. With its advanced technology and user-friendly interface, it is an ideal solution for various applications in fields such as industrial research, quality control, and non-destructive testing.

Featuring a robust and compact design, the Nikon XT H 225 offers exceptional flexibility and versatility, allowing for easy integration into existing workflows. The system is equipped with a high-power X-ray source, ensuring reliable imaging performance and capturing the finest details with precision.

One of the key highlights of the Nikon XT H 225 is its exceptional image quality. It utilizes advanced image processing algorithms that enhance contrast and minimize noise, resulting in clear and highly detailed X-ray images. This allows users to detect defects, measure dimensions, and analyze the internal structures of various materials with ease.

The intuitive software interface of the X-ray Nikon XT H 225 simplifies the acquisition, analysis, and sharing of X-ray images. With its user-friendly controls, operators can easily adjust exposure parameters, select imaging modes, and navigate through image datasets effortlessly. The system also supports advanced image analysis software, enabling users to perform measurements, annotations, and 3D reconstructions for in-depth data interpretation.

Furthermore, the X-ray Nikon XT H 225 offers seamless connectivity options, allowing for easy data transfer and integration into existing laboratory or industrial networks. It supports multiple file formats, making it compatible with various software applications for further analysis and documentation.

Applicattions:

Fault detection and failure analysis

Assembly inspection of complex mechanisms

Dimensional measurement of internal components

Part-to-CAD comparison

Advanced material research

Digital archiving of models

Key benefits

Easy system operation and low cost-of-ownership

High performance image acquisition and volume processing

Proprietary 225 kV microfocus X-ray source with 3 µm focal spot size

Safety first

Straightforward inspection automation

Stunning images providing great insight

| Microfocus source | Max. kV | Max. power | Focal spot size | Focal spot size |

| 160 kV Reflection target | 160 kV | 225 W | 3 µm up to 7 W | 225 µm at 225 W |

| 180 kV Transmission target | 180 kV | 20 W | 1 µm up to 3 W | 20 µm at 20 W |

| 225 kV Reflection target | 225 kV | 225 W | 3 µm up to 7 W | 225 µm at 225 W |

| Detectors | # Bits | Active pixels | Pixel Size | Max. frame rate at | Max. frame rate at |

| 1x1 binning | 2x2 binning | ||||

| Varian 1313Dx | 16-bit | 1000 x 1000 | 127 µm | 30 fps | 60 fps |

| Varian 2520Dx | 16-bit | 1900 x 1500 | 127 µm | 12.5 fps | 30 fps |

| Varex 4343 | 16-bit | 2880 2880 | 150 µm | 15 fps | 30 fps |

| Perkin Elmer 0820 | 16-bit | 1000 x 1000 | 200 µm | 7.5 fps | 15 fps |

Basic configuration

Alternative configuration

| Manipulator | XT H 160/ XT H 225 | General | ||

| # Axes | 5 | Cabinet dimensions (LxWxH) | 1,830 mm x 875 mm x 1,987 mm | |

| Axes travel | (X) 185 mm | Weight | 2,400 kg | |

| (Y) 250 mm | Safety | All systems are manufactured to IRR99 | ||

| (Typical values - Exact values depend on system configuration) | (Z) 625 mm | Control software | All systems are controlled by Nikon Metrology’s in-house Inspect-X software | |

| (Tilt) +/- 30 | ||||

| (Rotate) n*360° | ||||

| Max. sample weight | 15 kg |

Application

Featuring a robust and compact design, the Nikon XT H 225 offers exceptional flexibility and versatility, allowing for easy integration into existing workflows. The system is equipped with a high-power X-ray source, ensuring reliable imaging performance and capturing the finest details with precision.

One of the key highlights of the Nikon XT H 225 is its exceptional image quality. It utilizes advanced image processing algorithms that enhance contrast and minimize noise, resulting in clear and highly detailed X-ray images. This allows users to detect defects, measure dimensions, and analyze the internal structures of various materials with ease.

The intuitive software interface of the X-ray Nikon XT H 225 simplifies the acquisition, analysis, and sharing of X-ray images. With its user-friendly controls, operators can easily adjust exposure parameters, select imaging modes, and navigate through image datasets effortlessly. The system also supports advanced image analysis software, enabling users to perform measurements, annotations, and 3D reconstructions for in-depth data interpretation.

Furthermore, the X-ray Nikon XT H 225 offers seamless connectivity options, allowing for easy data transfer and integration into existing laboratory or industrial networks. It supports multiple file formats, making it compatible with various software applications for further analysis and documentation.

Applicattions:

Fault detection and failure analysis

Assembly inspection of complex mechanisms

Dimensional measurement of internal components

Part-to-CAD comparison

Advanced material research

Digital archiving of models

Key benefits

Easy system operation and low cost-of-ownership

High performance image acquisition and volume processing

Proprietary 225 kV microfocus X-ray source with 3 µm focal spot size

Safety first

Straightforward inspection automation

Stunning images providing great insight

Specifications

| Microfocus source | Max. kV | Max. power | Focal spot size | Focal spot size |

| 160 kV Reflection target | 160 kV | 225 W | 3 µm up to 7 W | 225 µm at 225 W |

| 180 kV Transmission target | 180 kV | 20 W | 1 µm up to 3 W | 20 µm at 20 W |

| 225 kV Reflection target | 225 kV | 225 W | 3 µm up to 7 W | 225 µm at 225 W |

| Detectors | # Bits | Active pixels | Pixel Size | Max. frame rate at | Max. frame rate at |

| 1x1 binning | 2x2 binning | ||||

| Varian 1313Dx | 16-bit | 1000 x 1000 | 127 µm | 30 fps | 60 fps |

| Varian 2520Dx | 16-bit | 1900 x 1500 | 127 µm | 12.5 fps | 30 fps |

| Varex 4343 | 16-bit | 2880 2880 | 150 µm | 15 fps | 30 fps |

| Perkin Elmer 0820 | 16-bit | 1000 x 1000 | 200 µm | 7.5 fps | 15 fps |

Basic configuration

Alternative configuration

| Manipulator | XT H 160/ XT H 225 | General | ||

| # Axes | 5 | Cabinet dimensions (LxWxH) | 1,830 mm x 875 mm x 1,987 mm | |

| Axes travel | (X) 185 mm | Weight | 2,400 kg | |

| (Y) 250 mm | Safety | All systems are manufactured to IRR99 | ||

| (Typical values - Exact values depend on system configuration) | (Z) 625 mm | Control software | All systems are controlled by Nikon Metrology’s in-house Inspect-X software | |

| (Tilt) +/- 30 | ||||

| (Rotate) n*360° | ||||

| Max. sample weight | 15 kg |