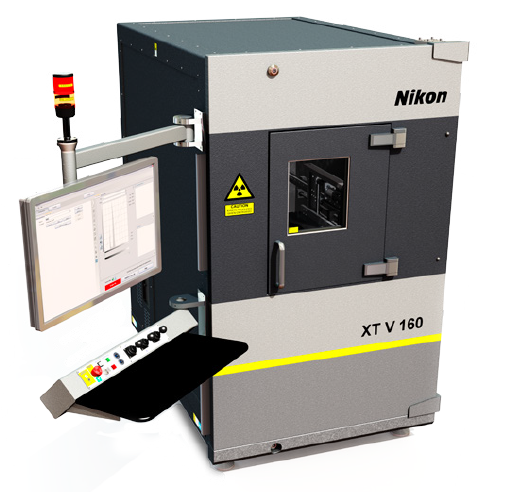

X-RAY NIKON XT V 160

X-RAY NIKON XT V 160

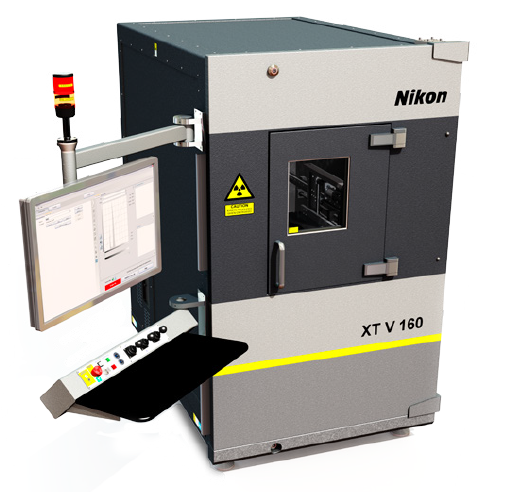

Model: XT V 160

Brand: Nikon

Origin:

Summary

The X-ray NIKON XT V 160 is a high-resolution imaging system designed for industrial x-ray and computed tomography applications. It offers superior imaging capabilities with a 16-megapixel cooled CCD camera and a 160kV micro-focus x-ray source.

Some features of the X-ray NIKON XT V 160 include:

- High-resolution x-ray imaging with exceptional contrast and detail

- Fast scanning and reconstruction times for high-throughput applications

- Automated imaging options for enhanced efficiency and accuracy

- Dual-energy imaging capabilities for material discrimination and identification

- User-friendly software interface for easy operation and data analysis

Overall, the X-ray NIKON XT V 160 is an ideal system for non-destructive testing and analysis in a wide range of industries, including aerospace, automotive, electronics, and more.

Sure, I'd be happy to expand on the features of the X-ray NIKON XT V 160.

One of the key features of the X-ray NIKON XT V 160 is its high-resolution imaging capabilities. The system incorporates a 16-megapixel cooled CCD camera that allows for detailed and precise imaging. This makes the X-ray NIKON XT V 160 ideal for applications that require accurate inspection of small components, such as electronics, medical devices, and precision parts.

Another advantage of the X-ray NIKON XT V 160 is its fast scanning and reconstruction times. The system can scan and reconstruct large samples quickly, allowing for high-throughput inspection and analysis. This is especially important in manufacturing settings where efficiency and speed are critical.

The X-ray NIKON XT V 160 also offers automated imaging options, which can improve efficiency and reduce user error. With features like automated stitching and automatic region of interest selection, users can streamline the imaging process and ensure consistent and accurate results.

One of the most advanced features of the X-ray NIKON XT V 160 is its dual-energy imaging capabilities. This feature allows for material discrimination and identification, making it ideal for applications where the composition of a sample is critical. For example, in the aerospace industry, it can be used to identify different types of alloys in a turbine blade.

Finally, the X-ray NIKON XT V 160 has a user-friendly software interface that makes it to operate and analyze data. The software includes advanced image processing algorithms, visualization tools, and measurement functions, allowing users to inspect and analyze their samples with ease.

Overall, the X-ray NIKON XT V 160 is a versatile and powerful imaging system that is ideal for a wide range of industrial applications. Its high-resolution imaging capabilities, fast scanning times, automated features, dual-energy imaging, and user-friendly software make it an excellent choice for non-destructive testing and analysis.

The X-ray Nikon XT V 160 has many applications in the industrial sector. Here are some of the main applications of the X-ray Nikon XT V 160:

Product quality inspection: The X-ray Nikon XT V 160 is widely used to inspect product quality in industries such as material manufacturing, precision engineering, and die-casting. Using the X-ray Nikon XT V 160 helps to evaluate product quality, detect defects and identify potential improvements for products.

Welding quality inspection: The X-ray Nikon XT V 160 is also used for welding quality inspections in the industrial sector. Using the machine helps to evaluate the quality of the welding connection, and assess the durability of the weld.

Material research: The X-ray Nikon XT V 160 is used for researching various materials. Experts can use the machine to examine the properties of materials, detect the homogeneity of the materials, and study the behavior of materials when influenced by external factors.

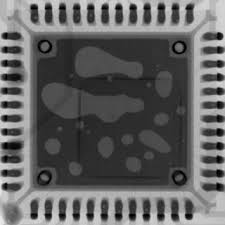

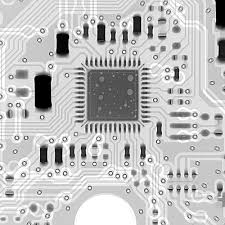

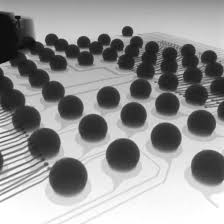

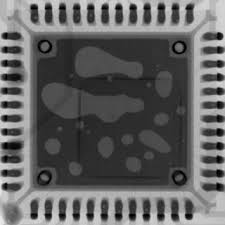

Electronic component testing: The X-ray XT V 160 is widely used for testing electronic components. Using the machine helps to evaluate the quality of electronic components, detect faults and improve the manufacturing process.

3D image reconstruction: The X-ray Nikon XT V 160 has the ability to take quick and accurate 3D images of samples. This feature helps experts analyze and the quality and properties of samples more easilyOverall, the various applications of the X-ray Nikon XT V 160 show that it is a valuable tool for ensuring product quality, identifying potential improvements for products, and researching materials.

Application

Overall, the X-ray NIKON XT V 160 is an ideal system for non-destructive testing and analysis in a wide range of industries, including aerospace, automotive, electronics, and more.

Sure, I'd be happy to expand on the features of the X-ray NIKON XT V 160.

One of the key features of the X-ray NIKON XT V 160 is its high-resolution imaging capabilities. The system incorporates a 16-megapixel cooled CCD camera that allows for detailed and precise imaging. This makes the X-ray NIKON XT V 160 ideal for applications that require accurate inspection of small components, such as electronics, medical devices, and precision parts.

Another advantage of the X-ray NIKON XT V 160 is its fast scanning and reconstruction times. The system can scan and reconstruct large samples quickly, allowing for high-throughput inspection and analysis. This is especially important in manufacturing settings where efficiency and speed are critical.

The X-ray NIKON XT V 160 also offers automated imaging options, which can improve efficiency and reduce user error. With features like automated stitching and automatic region of interest selection, users can streamline the imaging process and ensure consistent and accurate results.

One of the most advanced features of the X-ray NIKON XT V 160 is its dual-energy imaging capabilities. This feature allows for material discrimination and identification, making it ideal for applications where the composition of a sample is critical. For example, in the aerospace industry, it can be used to identify different types of alloys in a turbine blade.

Finally, the X-ray NIKON XT V 160 has a user-friendly software interface that makes it to operate and analyze data. The software includes advanced image processing algorithms, visualization tools, and measurement functions, allowing users to inspect and analyze their samples with ease.

Overall, the X-ray NIKON XT V 160 is a versatile and powerful imaging system that is ideal for a wide range of industrial applications. Its high-resolution imaging capabilities, fast scanning times, automated features, dual-energy imaging, and user-friendly software make it an excellent choice for non-destructive testing and analysis.

The X-ray Nikon XT V 160 has many applications in the industrial sector. Here are some of the main applications of the X-ray Nikon XT V 160:

Product quality inspection: The X-ray Nikon XT V 160 is widely used to inspect product quality in industries such as material manufacturing, precision engineering, and die-casting. Using the X-ray Nikon XT V 160 helps to evaluate product quality, detect defects and identify potential improvements for products.

Welding quality inspection: The X-ray Nikon XT V 160 is also used for welding quality inspections in the industrial sector. Using the machine helps to evaluate the quality of the welding connection, and assess the durability of the weld.

Material research: The X-ray Nikon XT V 160 is used for researching various materials. Experts can use the machine to examine the properties of materials, detect the homogeneity of the materials, and study the behavior of materials when influenced by external factors.

Electronic component testing: The X-ray XT V 160 is widely used for testing electronic components. Using the machine helps to evaluate the quality of electronic components, detect faults and improve the manufacturing process.

3D image reconstruction: The X-ray Nikon XT V 160 has the ability to take quick and accurate 3D images of samples. This feature helps experts analyze and the quality and properties of samples more easilyOverall, the various applications of the X-ray Nikon XT V 160 show that it is a valuable tool for ensuring product quality, identifying potential improvements for products, and researching materials.